In the face of a rapidly warming planet, the quest for sustainable solutions within the aviation industry has never been more critical. As air travel continues to connect us across continents and with passenger number set to double by 2050, it is a pressing challenge to substantial reduce carbon footprint of air travel. Enter Sustainable Aviation Fuel (SAF) – a ground-breaking innovation poised to revolutionize the skies. This article explores the promise of SAF, an eco-friendly alternative to conventional jet fuel, which stands at the forefront of the aviation industry’s fight against climate change. By delving into the science, the success stories, and the strategies for widespread adoption, we uncover the potential of SAF to not only mitigate environmental impact but also to propel the aviation sector towards a more sustainable and resilient future. Join us on this journey through the clouds, where sustainability meets innovation, and discover how SAF is setting the course for a greener horizon.

The depletion of the ozone layer as a result of greenhouse gas emissions (GHG) has led to an increase in natural disasters. In Malaysia, the energy sector accounts for 78.5% of GHG emissions, as reported in the Fourth Biennial Update Report submitted to the UNFCC (2022). The transportation sector is one of the energy-producing sectors that contributes to GHG emissions due to the use of fossil-based fuels in the internal combustion engine (ICE) of land vehicles and in aircraft gas turbine jet engines. International Civil Aviation Organization (ICAO) stated the aviation industry accounted for approximately 2.5% of GHG in 2019. This figure is projected to more than double by 2050 without effective measures to reduce emissions. As of 2022, the global aviation fuel market is worth approximately USD198.7 billion (RM941.62 billion) and is expected to reach USD252.8 billion by 2030. Sustainable aviation fuel (SAF) presents a potential solution to the aforementioned issues. However, there are hurdles involving the feedstock for SAF production, the process of converting feedstock to SAF, and the cost of SAF production.

The aviation industry accounted for approximately 2.5% of GHG in 2019 and the global aviation fuel market is worth approximately USD 198.7bn.

Sustainable aviation fuels is a potential solution to the GHG issues related to aircrafts, but there are numerous hurdles.

SAF is currently the most viable solution to address the sustainability challenges in the aviation industry. The higher cost of SAF compared to traditional jet fuel currently is a significant barrier. To overcome this challenge, there is an urgent need for innovation across the entire lifecycle of SAF, including procurement, refining, transportation, and infrastructure. By making SAF more accessible and affordable for both travellers and airlines, the industry can reduce its carbon footprint, which is projected to reach 3% of the global carbon emissions by 2050.

The cultivation of SAF has the potential to positively impact societies with extensive unsuitable land for food crop growth. By dedicating these areas to SAF crop production, airlines can achieve feedstock security, while local communities can benefit economically

Does cultivation of SAF lead to negative impacts?

UK Case Study:

In the UK, the SAF industry is anticipated to deliver nearly £3 billion in gross value, secure over 20,000 jobs, and save 3.6 million tonnes of CO2 annually by 2038. This would bring about numerous opportunities for investment, technology export, and job creation, benefiting workers, businesses, and societies across the UK.

Furthermore, the wider infrastructure and development of SAF across the country and globally would be significantly impacted. Malaysia possesses a substantial amount of arable land suitable for growing crops such as palm oil and other biofuels, which can be processed into aviation biofuels. The states of Sabah and Sarawak have a considerable amount of available land, with 77% of Malaysia’s cultivable land dedicated to palm tree farming, producing 85% of the world’s total palm oil. However, there needs to be a balance on using the crops for food and SAF as this could put pressure on the cost of food in the long term.

SAF also have the potential to reduce carbon dioxide (CO2) emissions by up to 84% per flight compared to conventional fossil fuels. Thus, it is crucial that the aviation industry takes a leading role in reducing its carbon footprint. To this end, governments must actively support the use of SAF by offering financial incentives such as grants, subsidies, and rewards to those who produce and use them.

The current high cost of SAF, which is four times that of fossil fuels, poses a significant challenge. Airlines may be forced to raise ticket prices to cover the increased costs, which could ultimately lead to their downfall and substantial losses. This suggests that the current use of SAF cannot guarantee a reduction in airfares due to the increased production costs.

Nevertheless, the long-term benefits of SAF in the aviation industry will be realized due to their improved fuel efficiency (around 1.5-3%), reduced CO2 emissions (>80%) and improved air quality (reduce up to 90% particulate and sulphur emission) resulting in a sustainable and eco-friendly future.

Sustainable feedstocks are key in the production of SAF

Sustainable raw materials are key in the development of SAF and these are classified into four different categories based on the type of feedstock utilized. These are important considerations as it will have an effect on food supply, cost and reduction of CO2 emissions.

The 1st generation of SAF uses edible bio-sources including soybean, sugarcane, wheat, oil palm, corn or palm oil. Nonetheless, utilizing edible bio-sources as feedstock presents a conflict with global food requirements, as it competes for land and freshwater resources.

The 2nd generation of SAF uses non-edible feedstock such as waste biomass and energy crops. Examples of waste biomass include wheat straw, corn stover, and palm kernel, while examples of energy crops include oilseeds, willow, eucalyptus, switchgrass, and elephant grass. Among these options, oil-seed plants are the most commonly used feedstock. The most frequently mentioned oil plants in the production of SAF include jatropha (Jatropha curcas) and camelina (Camelina sativa). Jatropha and Camelina are plants well-suited for oil production due to their high oil content, which accounts for 30-40% and 38-43% of their mass, respectively. They are not suitable as food sources for humans or animals because of their toxicity, making them ideal for cultivation on challenging lands such as arid and non-arable areas without competing with other crops for arable land.

In contrast, microorganisms like algae and micro algae are the 3rd and 4th generation feedstocks that do not require land or compete with food needs, making them a more sustainable option for fuel production. Algae are cultivated in suspension and require only sunlight, simple nutrients, and carbon dioxide to grow, making them ideal for cultivation in photo bioreactors or open areas. They absorb large amounts of carbon dioxide and pollutants during growth, purifying the air and water in which they thrive. However, the development stages of these SAF feedstocks are still in the early stages.

Most suitable and sustainable sources of feedstock would be those not conflicting with global food requirements.

In Malaysia, sustainability in the production of biofuels from palm oil is a challenge due to competition with food production for palm oil. Additionally, climate and weather conditions can impact sustainability efforts and affecting harvest yields. Despite advances in technology, such as the use of large greenhouses, the high cost of investment in building and maintaining such facilities for palm oil production makes it difficult to ensure sustainability in the production of palm oil for aviation biofuel purposes. Thus, the sustainability of palm oil production for SAF use requires a substantial investment.

Technological pathways for SAF

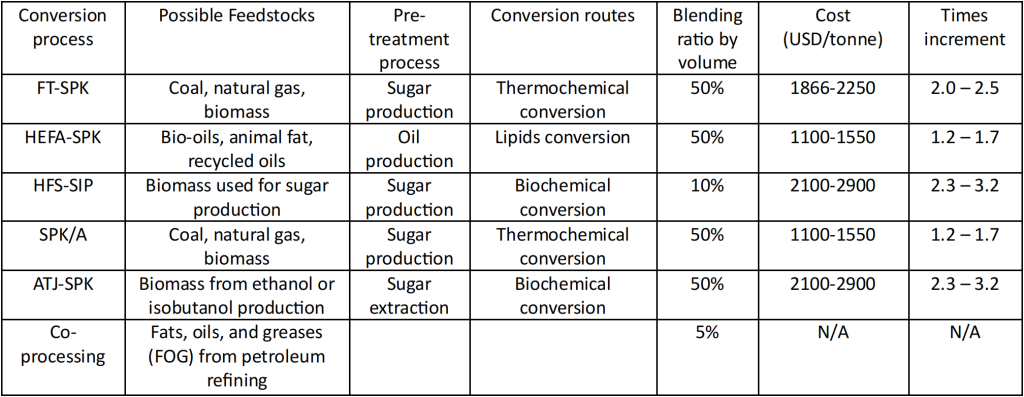

The SAF production pathway involves feedstock production, pre-treatment to meet the conversion process requirements, and the conversion process that produces aviation fuel. The conversion of feedstocks, into SAF can be done through various methods, such as biochemical, lipid, and thermochemical conversion.

Among these, the lipid conversion process is the most commonly used, as it involves hydrotreating or hydroprocessing lipids to produce hydroprocessed esters and fatty acids (HEFA), which have properties similar to conventional fuels. This process is currently the most widely recognized method of producing SAF and is comparable to refining petroleum. Hydroprocessing technologies that utilize vegetable and waste oils are the only conversion pathways that are ready for large-scale deployment.

Thermochemical conversion is a process that involves gasifying solid biomass at high temperatures to produce a mixture of gases, primarily carbon monoxide (CO) and hydrogen (H2), referred to as “syngas.” This syngas can be converted into a mixture of liquids and gases containing hydrocarbon chains of various sizes through the catalytic Fischer-Tropsch process (FT). The properties of the final products depend on factors such as the process temperature, catalysts used, and post-refining steps, including the separation of components in the mixture.

SAF can also be produced through the biochemical conversion of alcohol molecules such as ethanol or isobutanol, derived from sugar/starch-bearing plants and lignocellulosic materials through three key steps: dehydration, oligomerization, and hydrogenation. Alternatively, genetically modified microorganisms can be used to convert sugar into hydrocarbons or lipids, potentially producing substances such as farnesene (a synthetic iso-paraffin) that can be converted into a product with similar characteristics to aviation fuel.

FT-SPK: Synthesized Paraffinic Kerosene (SPK) from the Fischer-Tropsch process

HEFA-SPK: SPK from the Hydroprocessed Esters and Fatty Acids process

HFS-SIP: Synthetic Isoparaffins (SIP) from Hydroprocessed Fermented Sugars

ATJ-SPK: SPK from the Alcohol-to-Jet process

FT-SPK/A: FT-SPK with increased aromatic content

Role of Governments and Industries

The Malaysian government is dedicated to fostering the development and implementation of SAF as part of its initiative to reach carbon net zero by 2050. Malaysia’s active participation in Carbon Offsetting and Reduction Scheme for International Organisation (CORSIA) signifies its proactive role in addressing the critical issue of carbon emissions in aviation, aligning with its broader sustainability objectives. In furtherance of this goal, PETRONAS and Idemitsu Kosan Co., Ltd. signed a Memorandum of Understanding (MOU) in 2023 to enhance their capabilities across the supply chain and optimize the route to market for SAF. The MOU stipulate that PETRONAS and Idemitsu will conduct a feasibility study that will focus on several key areas, including scaling-up of bio feedstock possibilities, production cost analysis, and ensuring a stable and efficient supply chain for the sustainable growth of SAF. This study will also investigate the potential of non-edible oil feedstock trees, such as Pongamia and Jatropha, which are suitable for producing SAF. PETRONAS is making significant progress in its pursuit of cleaner energy solutions. By 2026, the company plans to have the capability to produce large quantities of SAF and other types of biofuels through its biorefinery in Pengerang, Johor and co-processing in Melaka.

Malaysia’s participation in Carbon Offsetting and Reduction Scheme International Organization signifies proactive role in addressing carbon emissions in aviation

PETRONAS is also collaborating with Sarawak Energy Corporation (SEC) to develop algae production technology for SAF. The project, which started in 2020, involves cultivating and harvesting algae and extracting crude algae oil, which will be refined to produce SAF. The collaboration with Japan’s Chitose Group, Sarawak Energy Bhd (SEB), and Sarawak Biodiversity Centre (SBC) is based on the suitable climate and abundant sea water in Sarawak for mass algae production. The project is targeting to enhance and scale up to 100ha and expand to 2,000ha in the future if it is commercially viable. PETRONAS and Neste also produce SAF using 100% renewable and sustainably-sourced waste and residue raw materials. In Malaysia, SAF production can be produced using approved sustainable biomass feedstock from algae, oil palm waste (empty fruit bunches @ EFBs), and agricultural and forestry residue. The inclusion of oil palm biomass as part of the CORSIA Eligible Fuel Criteria in 2021 was also supported by Malaysia’s efforts.

Petronas’ proactive approach to SAF:

- MOU with Idemitsu Kosan Co. Ltd for feasibility study on bio-feedstock possibilities and sustainable growth of SAF.

- Collaboration with Sarawak Energey Corporation to develop algae production for SAF.

Singapore announced a new levy on departing flights to fund the transition towards green jet fuel, specifically SAF, which is expected to increase ticket prices. Starting in 2026, all flights departing from Singapore will be required to use 1% SAF, with the goal to increase this to 3- 5% by 2030, depending on global developments. This initiative is part of Singapore’s efforts to address the aviation industry’s carbon emissions, which account for about 2% of global emissions. The levy’s impact on ticket prices will vary based on flight distance and class, with the increase for economy class tickets ranging from approximately S$3 to S$16 for flights to Bangkok, Tokyo, and London respectively. The plan comes amid broader discussions on how to finance the aviation sector’s shift to net zero emissions by 2050, which will require substantial capital investment.

Sustainable Aviation Fuel (SAF) stands at the vanguard of the aviation industry’s efforts to confront climate change, offering a viable pathway to drastically reduce its carbon footprint amidst rising global air travel. While SAF confronts challenges such as high production costs, feedstock availability, and the need for technological advancements, its potential benefits— ranging from significant emissions reduction to economic and social upliftment—underscore its critical role in achieving a greener future. The collaborative efforts between governments, industries, and the broader community are essential to surmount these obstacles, paving the way for SAF to transform air travel into a more sustainable, efficient, and environmentally friendly mode of transportation. As we stand on the precipice of a sustainability revolution in aviation, the adoption and widespread implementation of SAF not only aligns with global environmental goals but also opens up new avenues for sustainable development, making it an indispensable component of the industry’s journey towards a more sustainable horizon.